3D printing technology—also known as additive manufacturing-3D construction printinghttps://limenexus.com/

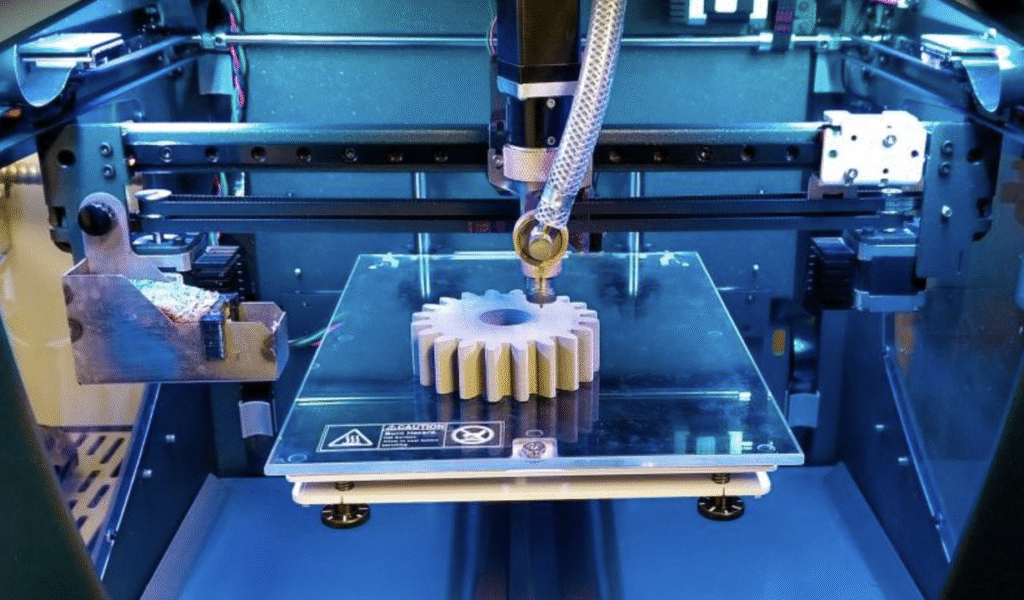

In today’s rapidly evolving construction landscape, 3D printing technology—also known as additive manufacturing—is reshaping how we build and maintain infrastructure. Although civil engineering is often associated with traditional construction methods, the integration of modern technologies such as 3D construction printing is unlocking new levels of efficiency, sustainability, and innovation.

✅ What is 3D Printing in Civil Engineering?

3D printing in civil engineering refers to the process of creating physical structures layer by layer using specialized printers and materials like concrete, polymers, metal, and composites. It enables engineers and architects to fabricate complex designs with precision, speed, and less waste.

As India transitions toward Industry 4.0, the construction sector—one of the largest contributors to the country’s GDP—is embracing 3D printing technologies to meet the growing demand for affordable housing, infrastructure development, and sustainable construction practices.

🏗️ Key Benefits of 3D Printing in Civil Engineering

Let’s explore some of the major advantages and real-world applications of 3D printing in construction and how they’re reshaping the Indian civil engineering industry.

1. ⏱️ Faster Construction with 3D Printing

Traditional construction methods are time-consuming and labor-intensive. In contrast, 3D printing accelerates construction by printing structures layer by layer with pre-programmed designs.

- Automated processes reduce manual labor.

- 3D construction printers can operate 24/7, unlike human workers.

- Speedy construction is ideal for low-cost housing projects in India and urban development schemes.

Example: A 3D printed house can be built in less than 48 hours, saving weeks compared to traditional construction timelines.

2. 💰 Reduced Construction Costs

3D printing reduces costs in multiple ways:

- Fewer laborers are needed on-site.

- Less material is wasted thanks to precise calculations.

- Reduced need for heavy machinery and formwork.

- Reusable 3D models save design costs.

For startups, contractors, and government schemes like Pradhan Mantri Awas Yojana (PMAY), 3D printing offers an economical way to build affordable homes in India.

3. 🧱 Construction of Complex Designs & Custom Structures

Traditional construction struggles with non-linear, futuristic architecture. However, 3D modeling and printing technologies allow engineers to:

- Experiment with curved, spiral, or asymmetric forms.

- Quickly update designs without extra cost.

- Print custom elements that are hard to create manually.

This flexibility makes 3D printing suitable for architectural innovation and luxury home construction in India.

4. 🏘️ Creation of Full 3D-Printed Structures

Civil engineers can now use 3D construction printers to print entire building elements like:

- Walls

- Floors

- Frames

- Roofs

Later, traditional components like plumbing, wiring, and insulation are added. India has already witnessed successful 3D-printed buildings, such as:

- TVASTA Manufacturing Solutions in Chennai, which built India’s first 3D printed house.

- Ongoing pilot projects in Bengaluru for printing public toilets and bus stops.

This signifies a major shift toward digitally-enabled construction methods in India.

5. 🧱 Stronger & Durable Structures

One misconception is that 3D-printed structures are weaker. In fact, these buildings:

- Offer uniform material distribution.

- Have fewer joints, reducing vulnerability to stress.

- Allow precise testing and calibration of material strength.

By using reinforced concrete, fiber-based composites, and geopolymers, civil engineers can build long-lasting buildings that require minimal maintenance.

6. 🌱 Sustainable & Eco-Friendly Homes

Environmental concerns are pushing India toward green construction. 3D printing supports this by:

- Using eco-friendly materials like mud, soil, bamboo composites, and recycled plastics.

- Minimizing construction waste.

- Reducing carbon emissions due to less transport and machinery use.

This makes 3D printing ideal for rural housing, eco-resorts, and smart city developments across India.

7. 🔧 Advanced Maintenance & Restoration Techniques

Maintenance of existing infrastructure is expensive and disruptive. 3D printing offers:

- Custom-made replacement parts for bridges, roads, and old buildings.

- Fast production of restoration elements for heritage sites in India.

- Innovative road maintenance using lightweight printable materials.

For example, certain bridge repairs can be carried out using 3D printed steel components without dismantling the entire structure.

8. ⛑️ 3D Printed Disaster Relief Shelters

Natural calamities like floods, earthquakes, and cyclones often leave thousands homeless. 3D printing helps governments and NGOs by:

- Rapidly building temporary or semi-permanent shelters.

- Using sustainable materials.

- Printing units on-site, even in remote areas.

Case Study: During the 2021 Kerala floods, proposals were made to deploy modular 3D printed homes as quick relief structures.

9. 🏘️ Urban Infrastructure Development

3D printing also aids civil engineers in planning and developing:

- Public toilets

- Pedestrian bridges

- Park benches

- Smart lamp posts

- Drainage systems

These elements can be produced off-site and assembled quickly with lower disruption to traffic and daily life.

10. 🧪 Innovation in Construction Materials

SEO Keywords: new construction materials, smart concrete, sustainable building materials India

R&D in 3D printing is pushing boundaries:

- Self-healing concrete

- Recycled plastic-infused cement

- Geopolymer mixtures

- Smart bricks with embedded electronics

Indian institutes like IIT Madras and IIT Hyderabad are actively researching new printable materials to promote self-sufficient building ecosystems.

🇮🇳 3D Printing and the Indian Construction Industry

India’s urban population is projected to reach 600 million by 2030, according to NITI Aayog. With this urban boom:

- India needs over 25 million affordable homes.

- Rural-to-urban migration demands rapid infrastructure development.

- Government initiatives like Housing for All, Make in India, and Smart Cities Mission emphasize tech-driven construction.

Hence, 3D printing in civil engineering can be a game-changer for India’s construction future.

🧩 Challenges in Adopting 3D Printing in Civil Engineering

While 3D printing has huge potential, some roadblocks remain:

| Challenge | Description |

|---|---|

| High Initial Cost | Industrial 3D printers cost crores; initial setup is expensive. |

| Skill Gap | Engineers and workers need training in digital modeling and operation. |

| Regulatory Approvals | Building codes and municipal laws need updates to include 3D printed structures. |

| Material Standardization | Lack of clear standards for 3D printable construction materials in India. |

However, ongoing public-private partnerships and investments in education and R&D are gradually addressing these issues.

📈 Future of 3D Printing in Civil Engineering

As the technology matures, expect the following trends in India:

- Integration of AI and IoT in printed homes

- On-site mobile 3D printers for rural development

- Use of 3D drones for building inspections

- Blockchain-based supply chains for material tracking

- Eco-friendly urban mobility infrastructure, such as printed metro stations and EV charging kiosks

🎯 Conclusion: A Revolution in the Making3D printing in civil engineering is more than just a tech trend—it’s a strategic solution for the challenges faced by the Indian construction industry. Whether it’s affordable housing, sustainable infrastructure, or post-disaster shelter creation, 3D construction printing can help India build faster, smarter, greener, and cheaper.

🚀 Final Thoughts

If you’re an engineer, builder, startup founder, or government official in India, it’s time to explore how additive manufacturing can revolutionize your projects. Investing in 3D printing technology now could future-proof your business for years to come.

📚 Frequently Asked Questions (FAQs)

Q1. Can 3D printing be used for commercial construction in India?

Yes, Indian firms have already started building commercial 3D-printed offices, retail stores, and hotels.

Q2. Is 3D printed housing safe and long-lasting?

Absolutely. With the right materials and design, 3D-printed homes can be as strong and durable as traditional buildings.

Q3. Are there any government initiatives promoting 3D construction in India?

While there’s no specific national program yet, several state governments and IITs are piloting 3D printing for housing and public infrastructure.

Q4. Can 3D printing reduce pollution in construction?

Yes, it uses less material, generates minimal waste, and enables greener construction processes.

Q5. What materials are used in 3D printed buildings in India?

Materials include concrete, geopolymer, recycled plastics, fly ash, clay, and soil blends.