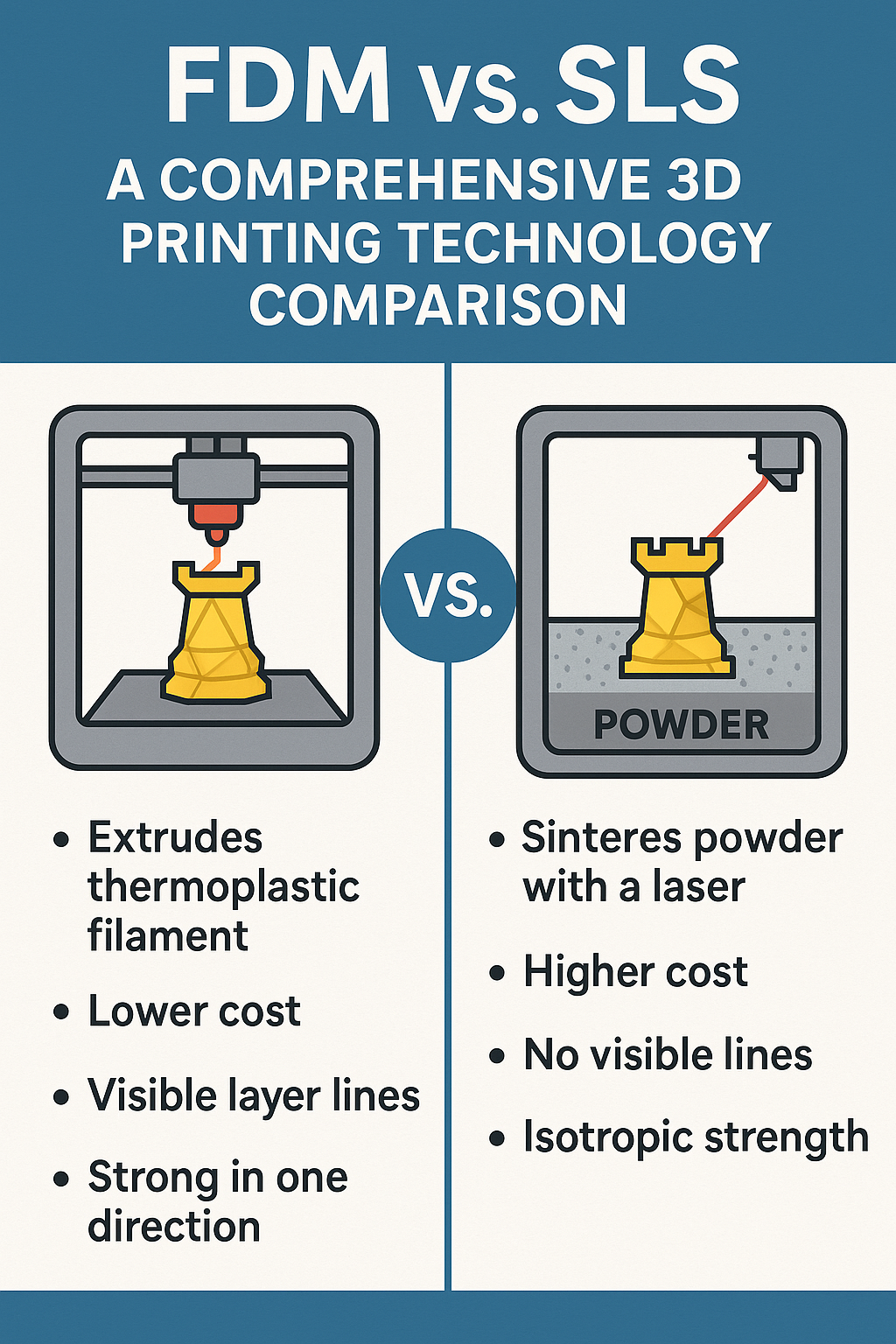

Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS)Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS)

What is FDM 3D Printing?

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is one of the most widely used additive manufacturing technologies. It works by melting thermoplastic filament and depositing it layer by layer through a heated nozzle.https://limenexus.com/

How FDM Works

- Filament Feeding: A spool of thermoplastic filament (like PLA, ABS, or PETG) is fed into the extruder.

- Melting & Extrusion: The filament is heated to a semi-liquid state and extruded through a nozzle.

- Layer-by-Layer Deposition: The extruder moves along the X, Y, and Z axes, building the object layer by layer.

- Cooling & Solidification: Each layer cools and hardens, bonding with the previous layer.

Key Features of FDM

✔ Affordable – Low-cost printers and materials.

✔ Wide Material Selection – PLA, ABS, PETG, TPU, Nylon, and more.

✔ Ease of Use – Beginner-friendly with minimal post-processing.

✔ Good for Large Parts – Can print large-scale objects.

Limitations of FDM

❌ Lower Accuracy & Resolution – Visible layer lines.

❌ Weak Interlayer Bonding – Prone to delamination.

❌ Limited Complexity – Requires support structures for overhangs.

What is SLS 3D Printing?

Selective Laser Sintering (SLS) is an industrial-grade 3D printing technology that uses a high-powered laser to fuse powdered material into solid structures. Unlike FDM, SLS doesn’t require support structures, making it ideal for complex geometries.

How SLS Works

- Powder Bed Preparation: A thin layer of powdered material (nylon, TPU, or composite) is spread across the build platform.

- Laser Sintering: A CO₂ laser selectively sinters (fuses) the powder particles.

- Layer Addition: A new powder layer is applied, and the process repeats.

- Cooling & Post-Processing: The printed part is removed from the powder bed, cleaned, and sometimes bead-blasted for a smoother finish.

Key Features of SLS

✔ High Strength & Durability – Fully dense, isotropic parts.

✔ No Support Structures Needed – Ideal for complex, intricate designs.

✔ Smooth Surface Finish – Better than FDM with minimal layer lines.

✔ Wide Range of Engineering Materials – Nylon (PA12), TPU, glass-filled, and carbon-filled powders.

Limitations of SLS

❌ Expensive – High machine and material costs.

❌ Limited Material Colors – Mostly white or gray unless dyed.

❌ Post-Processing Required – Excess powder removal needed.

FDM vs. SLS: Detailed Comparison

1. Print Quality & Accuracy

| Feature | FDM 3D Printing | SLS 3D Printing |

|---|---|---|

| Layer Resolution | 100-400 microns | 50-150 microns |

| Surface Finish | Rough, visible layer lines | Smoother, less visible layering |

| Dimensional Accuracy | ±0.5% (lower for hobbyist printers) | ±0.3% (higher precision) |

| Support Structures | Required for overhangs | Not required (self-supporting) |

Winner: SLS – Better resolution, smoother finish, and higher accuracy.

2. Material Options

| Feature | FDM 3D Printing | SLS 3D Printing |

|---|---|---|

| Common Materials | PLA, ABS, PETG, TPU, Nylon | Nylon (PA12), TPU, composites |

| Material Strength | Moderate (anisotropic) | High (isotropic) |

| Flexibility Options | TPU, TPE | Flexible TPU powders |

| High-Temp Resistance | Limited (ABS, Nylon) | Excellent (PA12, PEKK) |

Winner: SLS – More durable, functional materials with better mechanical properties.

3. Strength & Durability

- FDM: Parts are anisotropic (weaker along layer lines). Prone to delamination under stress.

- SLS: Parts are isotropic (equally strong in all directions). Ideal for functional prototypes and end-use parts.

Winner: SLS – Superior strength and durability for engineering applications.

4. Speed & Production Efficiency

- FDM: Faster for single large parts but slower for batch production.

- SLS: Slower per part but can print multiple parts simultaneously in a powder bed.

Winner: SLS – Better for small-batch manufacturing.

5. Cost Comparison

| Factor | FDM 3D Printing | SLS 3D Printing |

|---|---|---|

| Printer Cost | 200−200−5,000 | 20,000−20,000−500,000+ |

| Material Cost | 20−20−100/kg | 80−80−300/kg |

| Post-Processing Cost | Low (minimal sanding) | High (powder removal, dyeing) |

Winner: FDM – Far more affordable for hobbyists and small businesses.

6. Applications: Which One to Choose?

Best Uses for FDM:

✅ Prototyping (low-cost iterations)

✅ Hobbyist & Educational Projects

✅ Large, Simple Parts

✅ Functional Parts with Moderate Strength

Best Uses for SLS:

✅ High-Strength Functional Prototypes

✅ Complex, Intricate Geometries

✅ End-Use Production Parts

✅ Medical & Aerospace Components

Conclusion: FDM vs. SLS – Which Should You Choose?

- Choose FDM if: You need low-cost, simple prototypes, large parts, or are a beginner.

- Choose SLS if: You require high-strength, complex geometries, or industrial-grade parts.

Both technologies have their place in additive manufacturing, and the best choice depends on your budget, material needs, and application requirements.

Final Verdict:

✔ FDM = Best for Budget & Beginners

✔ SLS = Best for Professional & Industrial Use

By understanding these differences, you can make an informed decision on which 3D printing technology suits your project best.

SEO Keywords Used:

- FDM vs SLS

- 3D printing comparison

- Fused Deposition Modeling

- Selective Laser Sintering

- Best 3D printing technology

- FDM vs SLS strength

- SLS 3D printing advantages

- FDM material options

- Industrial 3D printing

- High-strength 3D printing